DC-CALC

Fast, Efficient Software for High Pressure Die Casting

![]() Software for Die Casting

Software for Die Casting

DC-CALC enables you to quickly calculate all the important process parameters for a new casting, to ensure feasibility and to design out the rejects.

DC-CALC brings together data from

- The casting

- The die

- The machine

to enable you to quickly establish the optimum design.

DC-CALC will greatly reduce the time spent doing simulations.

DC-CALC Main Modules

- Process Feasibility

Quickly establish if it is feasible to produce the part based on:

The machine chosen, the number of cavities, the gate area, the plunger diameter, the metal and die temperatures, the selected alloy.DC-CALC calculates cavity fill time, gate speed, plunger speed, filling pressure, shot end power, cavity filling flow rate and much more. - Gating and Runners

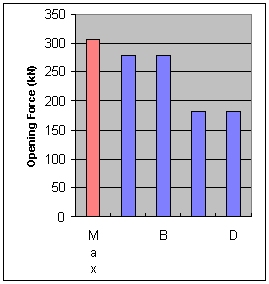

Quickly calculate and specify the dimensions of all the gates and runners to give to the die designer. - Die Locking Force

Calculates the force required to keep the dies closed during a high pressure shot, including the effect of offset cavities, impact pressure spikes and moving core slides. - Production and Cost Data

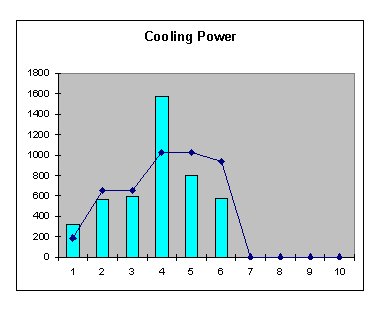

Establishes the die opening and closing times, the heat input to the die and the cost of the parts. - Thermal Balance

A quick calculation of the heat going in and the heat coming out of the die to identify and eliminate thermal problems upfront. - Pressure Venting

Calculates the total venting area in the die, including ejector pin clearances, the venting efficiency, and the expected casting porosity when using traditional vents. - Vacuum Venting

Specify the dimensions of all the vents and ducts for dies in which vacuum is to be used. Covers chill vents, zig-zag vents, serpentine vents, and mechanical valves. Calculates maximum achievable vacuum level and evacuation time. - Database of Machines and Alloys

DC-CALC is used for hot chamber and cold chamber Die Casting, large machines or small.It has a built-in database of machines and alloys, and you can easily add other data from your own plant.

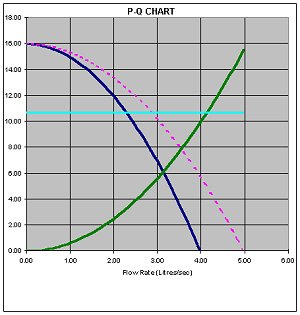

Plots the P-Q Chart for the die in the chosen machine

Displays a chart showing the opening force on each tie bar compared to the maximum allowed.

DC-CALC Features

- International and Multi-lingual

DC-CALC is used by Die Casting companies around the world.

It comes with 4 pre-installed language translations, and you can easily add up to 6 other languages.

Change the Language Number cell, and all screens will immediately re-display in the selected language. - License Fee for DC-CALC

The software license for DC-CALC is paid for in a single up-front payment. There are no annual fees or ongoing maintenance fees, so administration is easy.There is no limit to the number of DC-CALC users within the licensed organization, making it a very economical investment. - User Help

Users are supported with extensive help in applying and using DC-CALC:- A detailed User Help manual

- Context-sensitive links to online Help pages

- Email support on any aspect of the software

- Online Training for Technicians and Engineers

To gain the maximum benefit from using DC-CALC, users need to have a good grounding in the fundamentals of the high pressure Die Casting process. This is not taught at university or college, and company training programs do not normally provide this level of detail.To solve this issue, a license for DC-CALC includes enrollment in online training in 4 subjects:

- Fluid Flow in the Die Casting process

- Shot-End Characteristics of Die Casting Machines

- Feasibility and Die Layout

- Gating and Runner Design

Cooling Chart

Cost Chart