Advanced Shot Monitoring

- Reduce rejects using better information

- See what is happening inside your dies

- Measure cavity pressure directly

- Gain control over your process

Vacuum Die Casting

- Reduce porosity in your castings

- Add vacuum to dies at low cost

- Measure, monitor and control

Die Thermal Control

- High power cooling

- Maximum shot rate

- Precise pulse cooling

- Maximum process control

- The fastest way to remove heat from die casting dies and accurately maintain control of die temperature.

Our products

Die Thermal Control

High Power Cooling

Precision Control

Increase Production

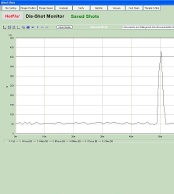

Advanced Shot Monitor

Eliminate defects

Troubleshooting

Monitor production

DC-CALC Software

Better die design

Process design

First shot success

Cavity Pressure Measurement

Detect porosity

Reduce flash

Troubleshooting

Cooling Line Meter

Measure cooling efficiency

Increase production

Avoid defects

Process Simulation

Flow path visualisation

Defect location

Advanced die design

Die Temperature Measurement

Monitor die temperature

Set targets

Activate alarms

Runner Design

Efficient flow path

Reduce trapped air

Calculated dimensions

Thermal Design

Maximum shot rate

Minimum porosity

Stable production

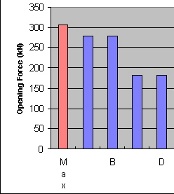

Lock-up Calculations

Predict die flash

Offset cavity calculations

Intensification pressure

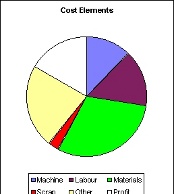

Product Costing

Accurate cost calculation

Machine Time Costs

Labour and on-costs

Venting Design

Vent sizes calculated

Predicted porosity

Reduce defects

Vacuum Design

Vent sizes calculated

Duct sizes calculated

Evacuation time calculated

Ejection Force Measurement

Avoid broken pins

Monitor lubrication

Process control

Tie Bar Monitor

Measure lock-up force

Accurate die setting

Avoid broken tie bars

USB Microscope

View casting defects

Establish root cause

Quality assurance

Shot Sleeve Selection

Calculate % fill

Calculate gate speed

Calculate fill time

Gate Optimisation

Alternatives evaluated

Parameters calculated

Dimensions specified

Machine Monitoring

Monitor every shot

Detect defects

Warn operators

Trouble Shooting

Portable Die-Shot

Identify root cause

Verify improvements