Hot Sprue Technology

Hot sprue technology is a process improvement for hot chamber Die Casting which:

- reduces wasted sprue and runner mass

- improves casting surface finish

- reduces gas porosity

- lowers Die Cast manufacturing cost

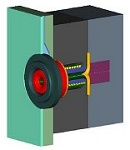

Hot Sprue Technology totally eliminates the sprue in hot chamber Die Casting and enables much smaller runners to be used. It provides a fully tapered metal feed path from the machine to the casting, improving the process capability.

The sprue bush and sprue post used in a traditional hot chamber Die Casting die are no longer required.

In its place is a Hot Sprue Kit, a set of precision components with an electric heating element, which maintains the alloy above its melting point and provides a smooth, unrestricted metal flow path.

The metal pressure losses are reduced, producing castings of better integrity.

The metal arrives at the gate with greater heat content improving casting surface quality.

The common causes of entrapped air in the feed system are eliminated leading to a reduction in casting porosity.

The massive reduction of sprues and runners reduces dross losses, energy use and manufactured cost.

The net result is an increase in quality, a decrease in costs and an increase in customer satisfaction.

Hot sprue technology is suitable for:

- Contract, jobbing or specialised Die Casting

- In-house, captive or cell based Die Casting

- Die Castings with high quality requirements

- Electroplated, powder coated and painted Die Castings, where every reject is a costly waste

- Horizontal hot chamber machines from 20 to 600 tons.

Hot sprue technology has been used in production for alloys of:

- Zinc

- Magnesium

- Lead

Standard Hot Sprue Kits are available for nozzle diameters of:

8.0mm, 12.0mm, 16.0mm, 20.0mm, 24.0mm

and

die thickness of:

60mm, 80mm, 100mm, 120mm and 150mm.

A 6mm insulation plate should be used with all hot sprue kits to reduce heat flow from the die to the platens.

Sprue tip styles are available in Mono, Duo and Tubular configurations.

Contact us to find out how you can implement hot sprue technology in your plant.